In the pursuit of a greener and more sustainable world, industries across the globe are embracing the concept of net zero emissions. Among these, the steel industry stands as a crucial player due to its significant environmental footprint. As demands for sustainability intensify, the steel sector faces both challenges and opportunities in its journey towards achieving net zero emissions.

The Challenge of Achieving Net Zero Emissions in the Steel Industry

The steel industry's carbon footprint primarily stems from two main sources: the use of carbon-intensive raw materials, such as coal and coke, in the production process, and energy-intensive operations involving high-temperature furnaces. These factors pose significant challenges to achieving net zero emissions:

- Carbon-Intensive Raw Materials: Traditional steelmaking processes rely heavily on coal and coke, which release substantial amounts of carbon dioxide (CO2) during combustion.

- Energy-Intensive Operations: The high temperatures required for steel production demand large amounts of energy, often sourced from fossil fuels.

- Technological Limitations: While alternative methods such as electric arc furnaces (EAF) offer lower emissions compared to traditional blast furnaces, they face limitations in scalability and cost-effectiveness.

Impacts of Inaction on Sustainability

Failure to adopt net zero and sustainability measures in the steel industry could lead to several detrimental consequences:

- Environmental Degradation: Continued reliance on carbon-intensive processes would contribute to worsening climate change and environmental degradation.

- Regulatory Compliance Issues: Governments and regulatory bodies are increasingly implementing stringent emissions regulations. Non-compliance could result in fines, penalties, and operational restrictions.

- Market Repercussions: Consumers are becoming more environmentally conscious, favoring products with lower carbon footprints. Steel companies that fail to adapt risk losing market share to competitors offering sustainable alternatives.

Digitalization: Areas of opportunity for the steel industry

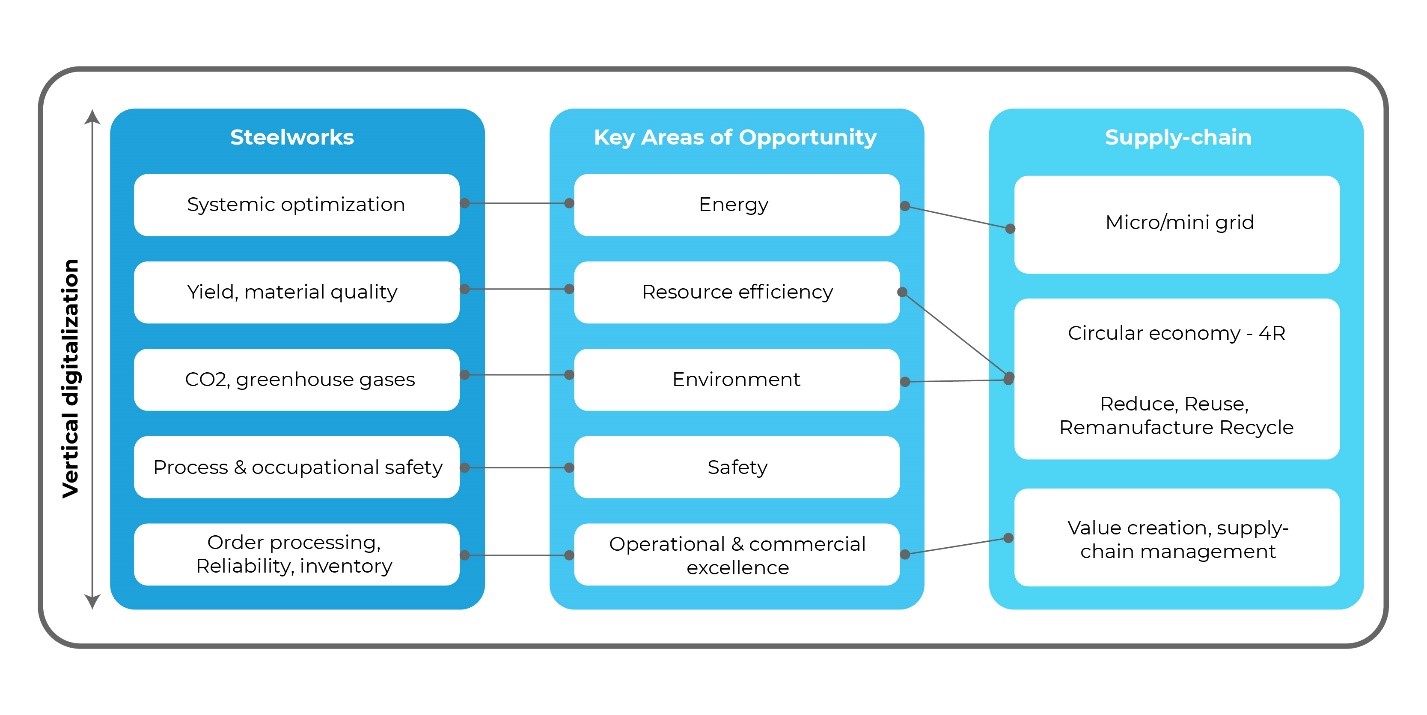

Digitalization in the steel industry reveals opportunities for systemic optimization, yield and material quality improvement, CO2 and greenhouse gas reduction, enhanced safety, and efficient order processing. It further drives energy conservation, resource efficiency, environmental protection, and operational excellence. Supply-chain innovation focuses on microgrids, the circular economy, and value creation in supply-chain management.

Leveraging Predictive Maintenance for Sustainability

One promising solution for the steel industry lies in the adoption of predictive maintenance practices. By leveraging advanced technologies such as Internet of Things (IoT) sensors, artificial intelligence (AI), and machine learning algorithms, steel plants can optimize their operations in several ways:

- Reducing Downtime: Predictive maintenance enables proactive identification of equipment failures before they occur, minimizing unplanned downtime and improving overall efficiency.

- Optimizing Energy Usage: AI-driven predictive analytics can analyze real-time data from machinery and processes to identify energy-saving opportunities, helping reduce energy consumption and carbon emissions.

- Enhancing Equipment Lifespan: By monitoring the condition of critical assets, predictive maintenance allows for timely repairs and replacements, prolonging the lifespan of equipment and reducing the need for resource-intensive manufacturing of new components.

- Minimizing Waste: Predictive maintenance can help identify and address inefficiencies in production processes, reducing material wastage and associated environmental impacts.

Conclusion

The steel industry stands at a crossroads, facing both the imperative to reduce its environmental footprint and the challenges inherent in traditional manufacturing processes. Embracing net zero emissions and sustainability initiatives is not only crucial for mitigating climate change but also for ensuring long-term competitiveness and resilience in an increasingly eco-conscious market. By adopting predictive maintenance practices alongside other innovative technologies, such as VIBit, steel companies can pave the way towards a more sustainable future, where economic prosperity coexists harmoniously with environmental stewardship.