Machine Anomaly Detection, Diagnostics,

and Preventive Maintenance

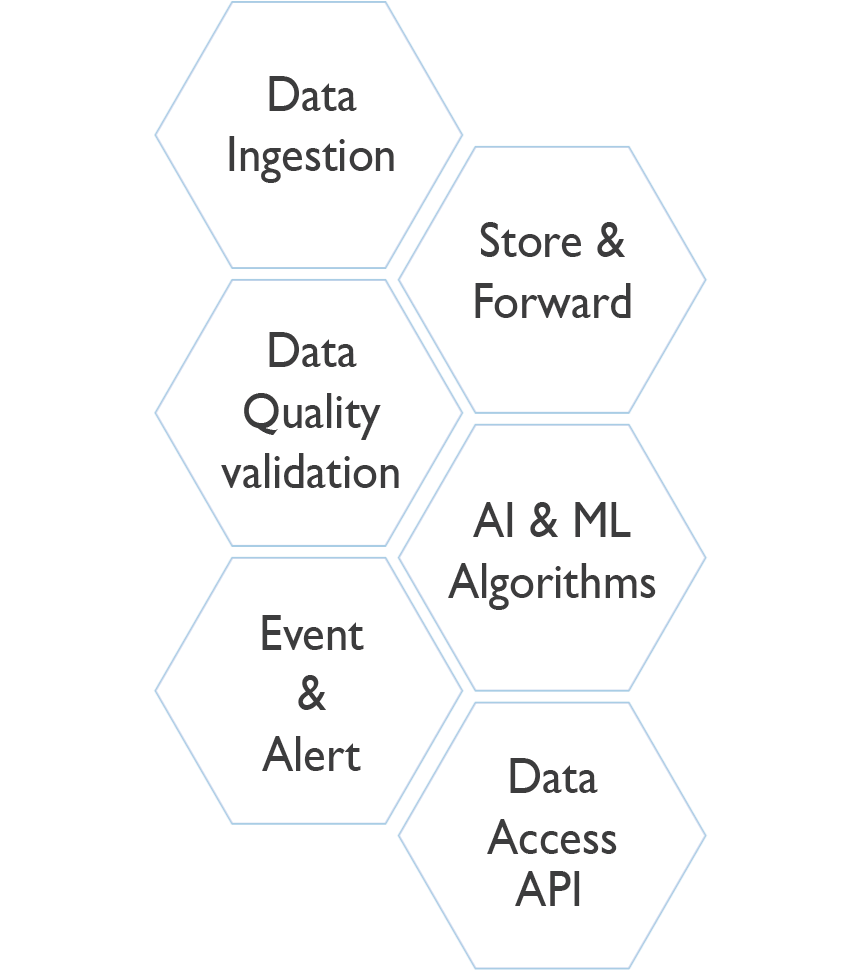

CIMCON Digital’s intelligent iEdge platform collects, integrates, and transforms data on machine health using AI technology. Working with next-generation predictive maintenance solutions, CIMCON Digital provides actionable intelligence and early warning on machines. This gives you the information needed to take corrective actions, preventing costly machine failures.

How the Solution Works

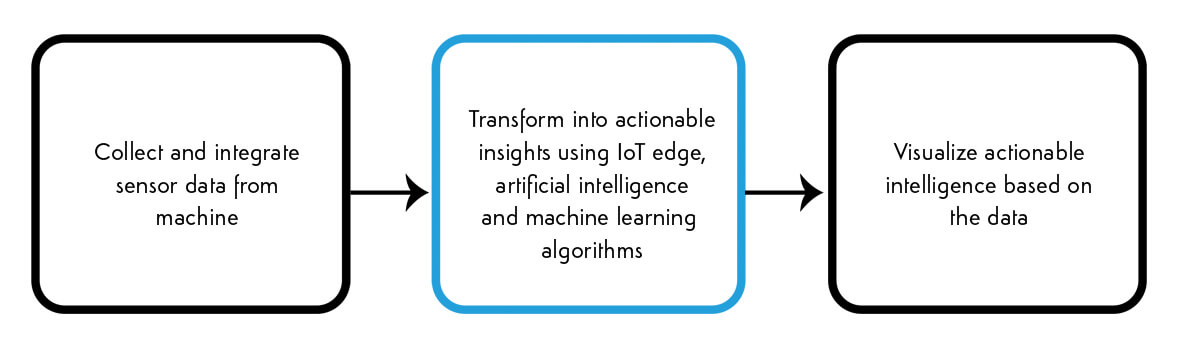

Our end-to-end solutions provide businesses with actionable insight on machine health and performance in 3 simple steps:

- RS 485 / RS 232

- Modbus

- TCP/IP

- Wi-Fi / Bluetooth

- 4-20 ma / 0-5 V / 0-10 V

Outcomes: Machine Health Key Performance Indicators (KPI’s)

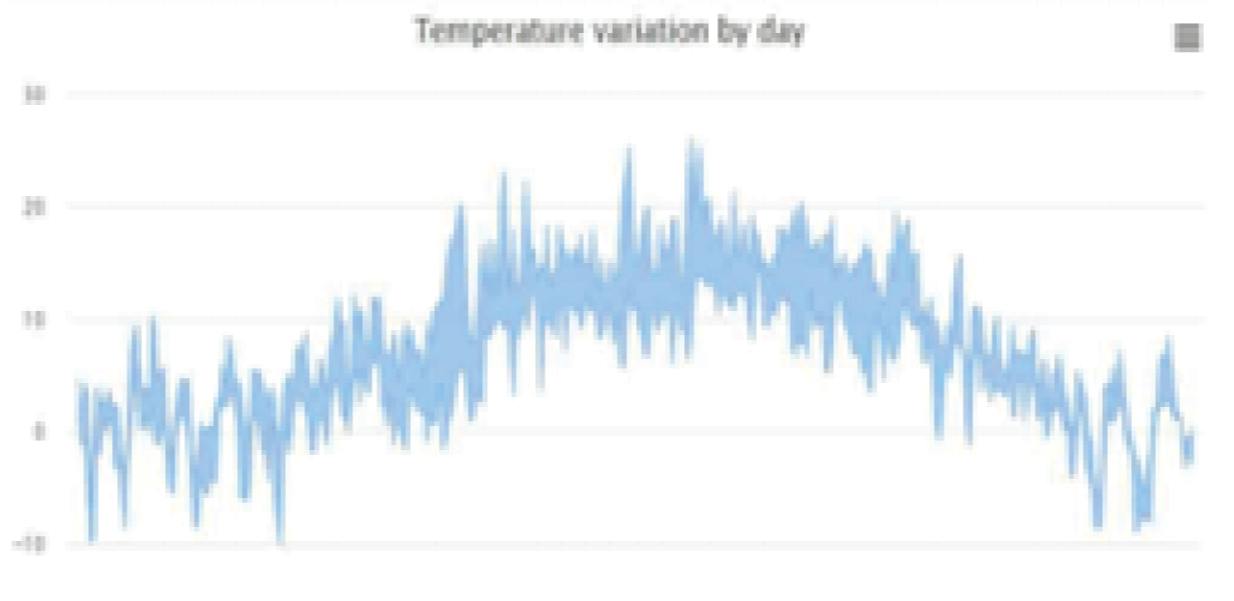

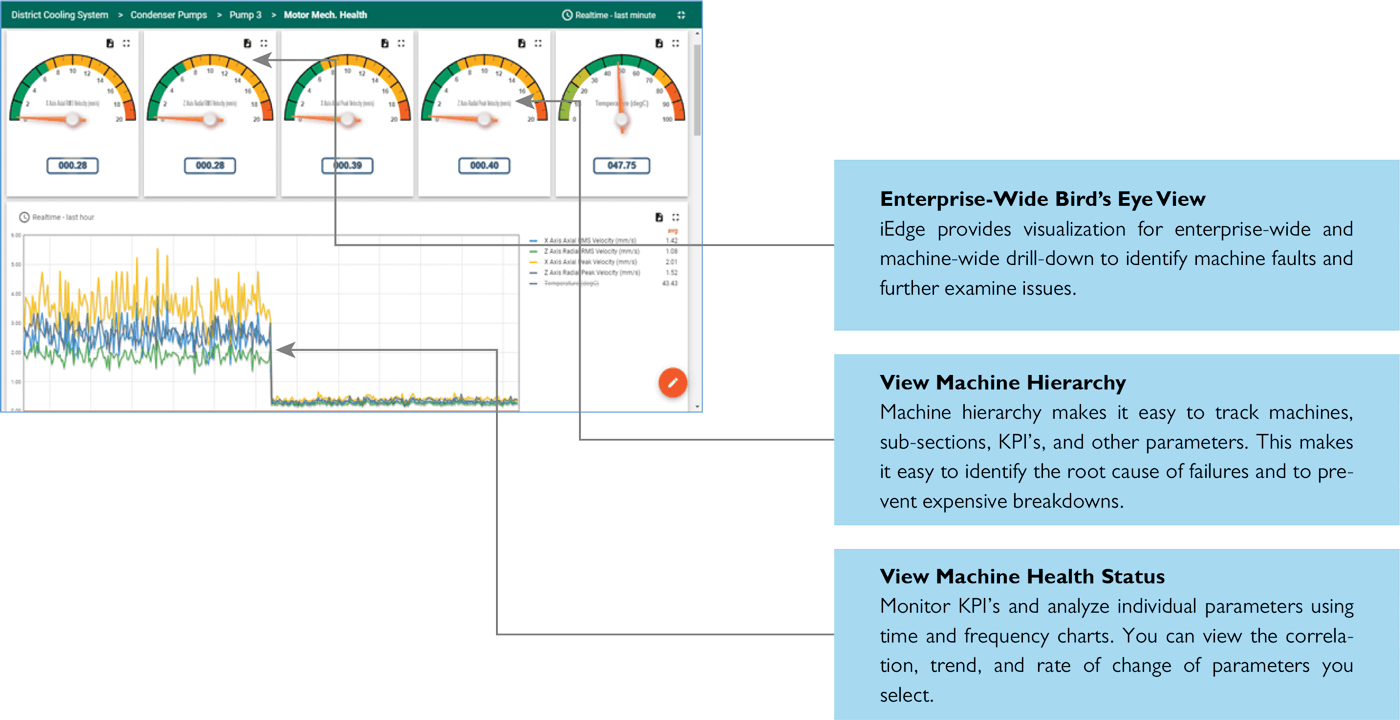

iEdge provides role- and KPI-based visualization of data in enterprise and machine hierarchy view. This mode of data visualization enables fast, easy analysis. That way, there is more time for the diagnosis and repair of machine faults.

Taking the Next Step: Preventive Maintenance

Implementation of predictive maintenance solution is a “journey” that starts with machine data capture and actionable alerts. The next step is implementing advanced anomaly detection to create a predictive maintenance system.

Using artificial intelligence and machine learning algorithms, the iEdge system acts as your best machine SME. It reviews sensor data 24 hours a day, 365 days a year. CIMCON digital solutions improve asset availability, reduce maintenance costs, and improve industrial safety.

The Last Step – Building a Digital Twin

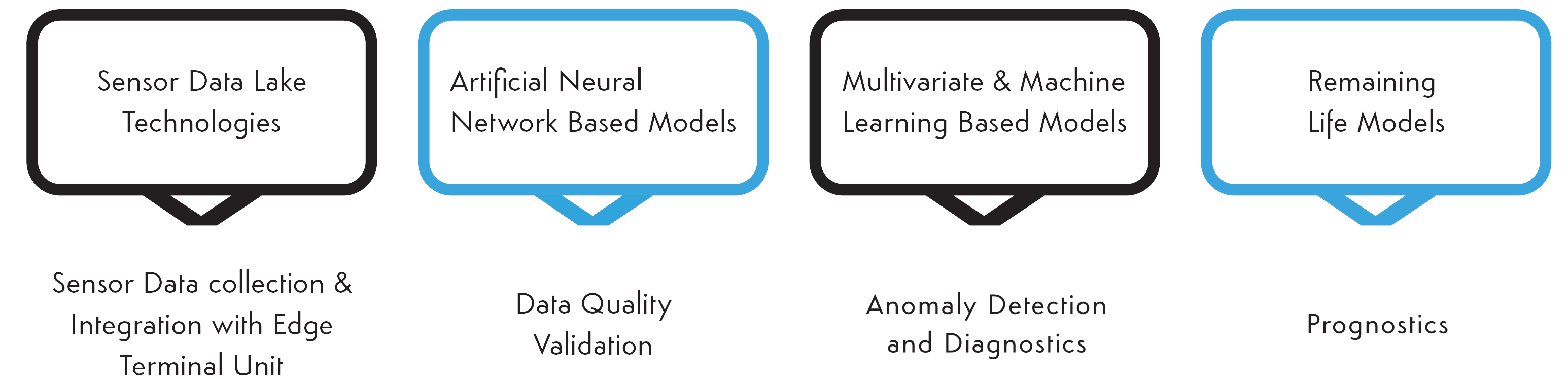

Leveraging the latest advances in artificial intelligence technology, machine learning algorithms, and multivariate statistical modeling, the CIMCON iEdge Platform can create a “Digital Twin” of your machine or asset. Our Digital Twin model provides prognostics and remaining useful life information. It also computes risk profiles over time. It provides an answer for questions like “When will this machine condition become critical?”

Sensor data quality plays a vital role in industrial IoT applications as they are rendered useless if the data quality is bad. Artificial Neural network-based sensor data validation algorithms identify outliers, missing data, constant value, stuck at zero, and filter bad data from useful data. This helps to increase data science productivity and accuracy of anomaly detection and diagnostics models significantly.

Control room operators/subject matter experts who monitor number of assets/parameters have limited ability to visualize small changes in individual sensor behaviors and identify correlation with other sensor or machine faults. In SCADA/PLC, the threshold value set for alerts by the plant or OEM are for warning and protection and cannot detect small changes in sensor deviation. In reality, most equipments fail as a result of slow-progressing fault modes and faults progressing independent of time.