The automobile industry is undergoing a significant transformation driven by digital technologies. As IoT (Internet of Things) and advanced analytics become integral to operations, automobile manufacturing plants are evolving into smart factories that prioritize efficiency, productivity, and proactive maintenance. This blog explores how digital transformation, particularly through predictive maintenance, is reshaping the landscape of automobile manufacturing.

Machine Anomaly Detection and Diagnostics

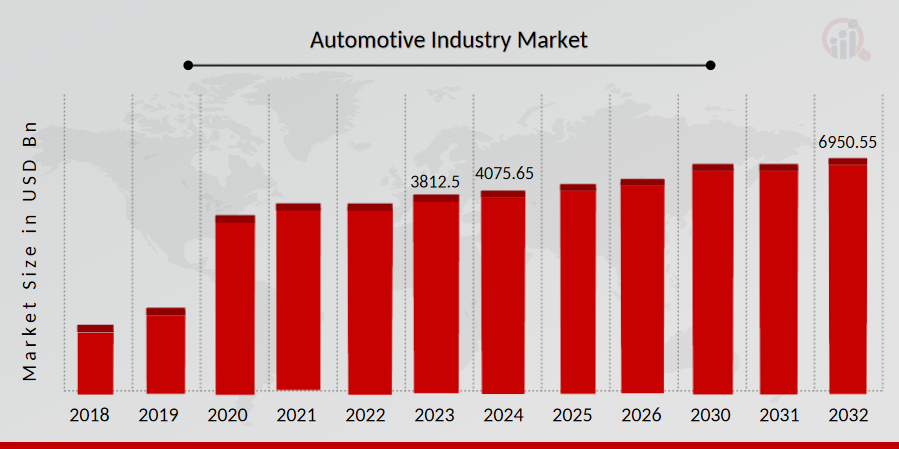

The Automotive Industry is expected to grow significantly, from USD 4075.65 billion in 2024 to USD 6950.55 billion by 2032, with a compound annual growth rate (CAGR) of 6.9% from 2024 to 2030. In 2023, the market was valued at USD 3812.5 billion. However, this growth brings challenges, including the need for higher efficiency, reduced downtime, and better asset management. Digital transformation plays a crucial role in addressing these challenges by providing tools and technologies that enhance operational capabilities.

Report by- https://www.marketresearchfuture.com/

Machine Anomaly Detection and Diagnostics

A key component of digital transformation in the automobile industry is the implementation of machine anomaly detection and diagnostics. This involves monitoring the health of critical machinery and identifying potential issues before they escalate into significant problems. The process includes:

Automatic Diagnostics and Recommendation (ADR): Utilizing AI and machine learning algorithms to diagnose equipment issues and recommend corrective actions.

Remaining Useful Life (RUL): Predicting the remaining operational life of machinery to plan maintenance activities effectively.

Pattern Recognition Models (SBM): Using advanced models to detect unusual patterns that indicate potential faults.

These technologies are integrated with sensors that monitor vibration, temperature, and acoustic signals, providing real-time data that is analyzed to generate actionable insights.

Enhancing Reliability with IoT and Edge Computing

The integration of IoT devices and edge computing is crucial for real-time monitoring and diagnostics. Key elements include:

Edge Hardware and Software: Devices that collect and process data at the edge of the network, ensuring quick and efficient analysis.

Cloud Integration: Centralizing data storage and analysis to provide comprehensive visibility across the entire manufacturing plant.

With a 98% reliability of IoT networks and 99% sensor data accuracy, these technologies ensure high system uptime and reliable operation of machinery.

Benefits of Predictive Maintenance

Predictive maintenance significantly enhances business value by transforming maintenance practices from reactive to proactive. Key benefits include:

Condition-Based Maintenance: Real-time machine data enables maintenance planning based on actual conditions rather than assumptions.

Prioritized Maintenance Actions: Intuitive dashboards and prescriptive diagnostics help prioritize maintenance activities.

Systemic Risk Insights: Understanding the health of assets and production lines allows for setting benchmarks and uncovering systemic risks.

Elimination of Unplanned Downtime: Predictive maintenance helps identify issues before they cause downtime, ensuring smooth operations.

Remote Collaboration: Maintenance teams can collaborate around a common set of machine health data, facilitating better decision-making.

Case Studies: Success Stories from Leading Manufacturers

Preventing Major Motor Failure

A notable example of predictive maintenance success is at press shop. By deploying the VIBit solution and iEdge360 IoT platform, the company prevented major motor failures and avoided significant production downtime. Real-time monitoring identified anomalies in

X-RMS acceleration and Y-RMS velocity, allowing timely interventions and saving considerable downtime and production losses.

Improving Efficiency

The implementation of predictive maintenance solutions led to early detection of bearing wear and structural stiffness issues. The maintenance team could plan and execute maintenance activities during non-production hours, significantly reducing unplanned downtime and enhancing overall efficiency.

Optimizing Performance at a Global Automobile Manufacturer

A global automobile manufacturer saw substantial benefits by digitizing asset performance management. The deployment of IoT edge devices and real-time condition monitoring prevented catastrophic machine failures, reduced maintenance costs, and improved productivity.

Digital transformation in automotive manufacturing significantly enhances the ability to manage and mitigate faults in machines through several key use cases:

- Predictive Maintenance: Utilizing IoT sensors and AI algorithms, predictive maintenance systems monitor machine performance and predict potential failures before they occur. This minimizes downtime and reduces maintenance costs by scheduling repairs only when necessary.

- Real-Time Monitoring and Diagnostics: Advanced sensor networks and data analytics tools provide real-time monitoring of machinery. This allows for immediate detection of anomalies or deviations from normal operating conditions, enabling swift interventions to prevent faults from escalating.

- Digital Twin Technology: Creating a digital twin a virtual replica of physical assets enables manufacturers to simulate and analyze machine performance. This helps in identifying potential issues and testing solutions in a virtual environment before applying them to the actual machines.

- Automated Quality Control: Machine learning algorithms analyze data from production lines to detect defects in real time. This ensures that faults are identified and corrected promptly, improving product quality and reducing waste.

- Remote Troubleshooting and Maintenance: With the integration of remote connectivity tools, technicians can diagnose and repair faults from remote locations. This speeds up the resolution process and minimizes the need for on-site visits.

- Data-Driven Decision Making: Collecting and analyzing vast amounts of data from machines allows manufacturers to gain insights into performance trends and recurring issues. This data-driven approach facilitates informed decision-making and strategic planning to enhance machine reliability and efficiency.

What is the future of digital transformation in automotive?

The future of digital transformation in automotive manufacturing is set to revolutionize the industry through advanced AI and machine learning, greater IoT integration, and the deployment of 5G connectivity. These technologies will enable smarter factories with real-time data-driven decision-making, predictive maintenance, and enhanced automation. Sustainability efforts will be bolstered by digital energy management and waste reduction systems, while blockchain technology will improve supply chain transparency and reliability. This evolution will lead to more efficient, flexible, and customer-centric manufacturing processes, driving the industry towards a highly connected and intelligent future.

Conclusion

Digital transformation through IoT and predictive maintenance is revolutionizing the automobile industry. By leveraging advanced analytics, real-time monitoring, and proactive maintenance strategies, manufacturers can achieve significant improvements.

Industry-leading manufacturers are experiencing up to a 50% reduction in machine downtime, a 30% increase in productivity, a 30% rise in throughput, and a 20% decrease in the cost of quality. For instance, by preventing a major motor failure in the press shop, some have saved 25 hours of downtime and INR 6,12,000 in production losses. These advancements not only address current challenges but also position the industry for future growth and innovation.

For more information on how digital transformation can benefit your automobile manufacturing plant, contact sales@cimcondigital.com or call +91-9512800836.