In the pharmaceutical industry, where precision and compliance are non-negotiable, equipment reliability is critical. Unplanned breakdowns can lead to costly delays, compromised product quality, and regulatory non-compliance. Condition-Based Monitoring (CBM) has emerged as a game-changing approach to enhance operational efficiency, reduce downtime, and maintain compliance with stringent regulations. This blog delves into the principles of CBM, its benefits, and its application in monitoring Air Handling Units (AHUs). Real-world examples, regulatory implications, and future trends further illuminate its significance.

What is Condition-Based Monitoring?

CBM is a proactive maintenance strategy that continuously monitors equipment health and performance using advanced technologies like sensors, data analytics, and predictive modeling. By analyzing real-time data, CBM identifies potential issues early, allowing maintenance teams to intervene before failures occur. This minimizes unexpected breakdowns and ensures smooth operations.

The condition-based monitoring (CBM) market is witnessing significant growth globally, driven by advancements in predictive maintenance technologies and increased adoption across industries.

Indian Market:

Indian machine condition monitoring market size is set to grow at a CAGR of 10.95% during the forecast period 2020-2025 and projected to reach $193.3 million by 2025.

Global Market:

The market is expected to continue growing at a 7.3% CAGR during the forecast period from 2024 to 2028. This growth is driven by advancements in technology, a stronger focus on predictive maintenance, and increased investments in industrial digitization.

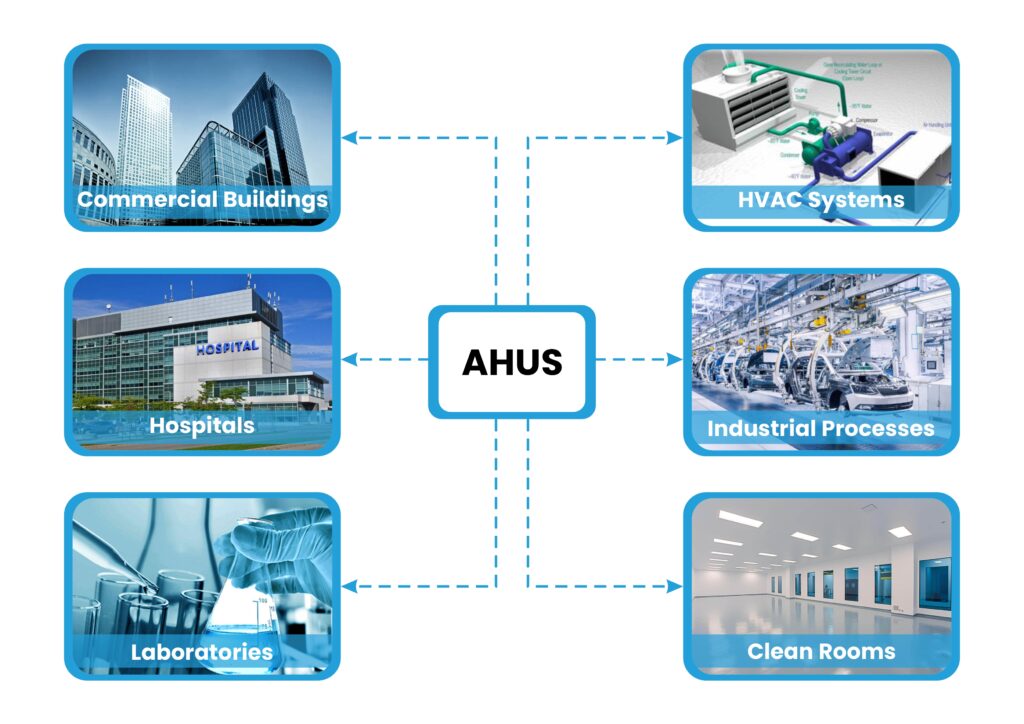

The Versatility of Air Handling Units (AHUs): Applications

Here’s how AHUs are commonly used:

- HVAC Systems

AHUs are essential in HVAC systems, controlling temperature, humidity, and air circulation. They create comfortable and healthy indoor conditions in spaces like offices, homes, and public buildings. - Industrial Applications

Industries like pharmaceuticals, food processing, and manufacturing rely on AHUs for precise environmental control. They help maintain specific conditions, such as temperature and humidity, critical for production quality. - Clean Rooms

Clean rooms require extremely low levels of dust and contaminants. AHUs in these environments maintain high air purity, stable temperatures, and controlled humidity, supporting sectors like biotechnology and semiconductor production. - Laboratories

In laboratories, AHUs maintain consistent temperature and humidity while ensuring proper ventilation. This prevents the buildup of harmful fumes, creating a safe and stable environment for experiments and research. - Hospitals

Hospitals use AHUs to ensure high air quality and prevent the spread of infections. They filter and circulate clean air throughout the facility, protecting patients and staff. - Commercial Buildings

AHUs are widely used in large commercial spaces such as malls, airports, and office buildings. They regulate indoor climates, circulate fresh air, and enhance energy efficiency.

Key Components of AHUs That Require Monitoring

Fans and Motors

Ensure consistent air circulation to meet cleanroom standards.

Coils

Manage heating and cooling processes for temperature control.

Dampers

Regulate airflow direction and volume.

Sensors

Given their critical function in safeguarding product quality and employee safety, comprehensive monitoring of AHUs is essential.

Condition Monitoring of AHUs

Key Monitoring Metrics

- Airflow and Pressure: Detect blockages or inefficiencies in filters through differential pressure sensors.

- Vibration Analysis: Identify fan misalignment or motor bearing wear.

- Temperature and Humidity: Maintain compliance with stringent cleanroom standards.

- Filter Health: Ensure timely replacement to maintain air quality.

- Energy Consumption: Identify inefficiencies in heating, cooling, or airflow systems.

Enabling Technologies

- IoT Sensors: Enable real-time data collection and seamless communication.

- Advanced Analytics: Predict anomalies and patterns for early intervention.

- Cloud-Based Systems: Facilitate data storage, trend analysis, and remote access.

- Machine Learning: Continuously improve predictions using historical data.

- Digital Twin Technology: Simulate AHU performance for predictive insights.

Real-World Applications

- Optimizing Filter Replacement: A pharmaceutical facility used IoT-enabled sensors to monitor filter conditions. By optimizing replacement schedules, it reduced operational costs by 20%.

- Energy Efficiency Gains: Through vibration and energy monitoring of AHU fans, another company addressed motor inefficiencies, reducing energy consumption by 15%.

At CIMCON, we’ve implemented CBM solutions for AHUs, achieving measurable improvements in performance and reliability.

Regulatory Implications of CBM

- GMP Compliance: Real-time monitoring ensures consistent environmental conditions and provides documentation for audits.

- FDA Standards: CBM supports stringent environmental controls and delivers evidence of compliance.

- ISO 14644: Aligns with cleanroom standards, ensuring proper air cleanliness.

Benefits of CBM for AHUs

- Proactive Maintenance: Conduct maintenance based on real-time equipment conditions.

- Regulatory Compliance: Maintain GMP and FDA-mandated standards effortlessly.

- Energy Optimization: Identify inefficiencies to lower energy usage.

- Extended Equipment Lifespan: Minimize wear and tear through timely interventions.

- Reduced Downtime: Prevent costly disruptions due to equipment failure.

- Improved Product Quality: Maintain stringent environmental controls for optimal outcomes.

Future Trends in CBM for AHUs

- AI-Powered Analytics: Enhance predictive capabilities for smarter maintenance planning.

- 5G Connectivity: Enable faster, more reliable data transmission.

- Integration with BMS: Holistic facility monitoring through Building Management Systems.

- Sustainability Metrics: Incorporate environmental impact data, such as carbon footprint tracking.

Steps to Implement CBM for AHUs

- Assess Systems: Identify critical components for monitoring.

- Deploy Sensors: Install sensors for airflow, vibration, and temperature.

- Integrate Data: Connect CBM systems with existing BMS platforms.

- Train Teams: Provide training to interpret data and act on insights.

- Audit Regularly: Evaluate system effectiveness and adapt strategies as needed.

Conclusion

Condition-based monitoring is revolutionizing pharmaceutical operations by enabling proactive and efficient maintenance strategies. For Air Handling Units (AHUs), which are critical to maintaining compliant and contamination-free environments, CBM ensures reliability, energy efficiency, and adherence to regulatory standards.

Investing in CBM for AHUs not only minimizes downtime and enhances product quality but also demonstrates a commitment to operational excellence. As the pharmaceutical industry continues to evolve, adopting advanced monitoring technologies will be essential for sustainable growth, regulatory compliance, and competitive advantage.

CIMCON Digital plays a pivotal role in this transformation by offering cutting-edge IoT-based CBM solutions tailored to the pharmaceutical industry. With expertise in integrating advanced analytics, real-time monitoring, and AI-powered insights, CIMCON Digital helps organizations optimize their maintenance strategies, reduce operational risks, and achieve regulatory compliance. Its VIBit system and IoT Edge platform are designed to provide precise, real-time data on equipment health, enabling predictive and prescriptive maintenance. By leveraging these innovations, pharmaceutical companies can achieve unparalleled operational efficiency, ensuring sustainability, quality, and innovation in their processes.