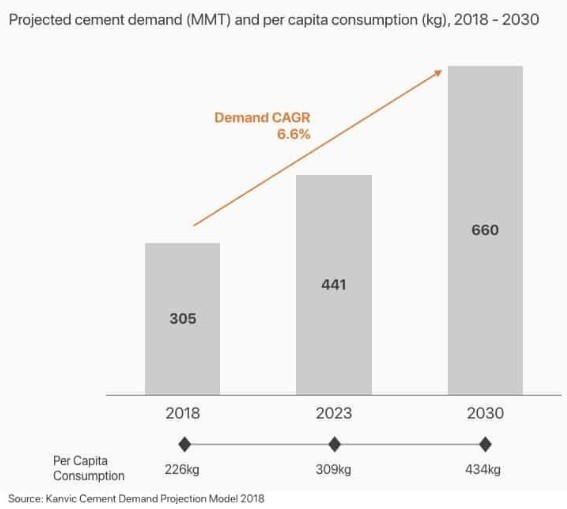

Industry Growth and Technological Advancements: As highlighted in a McKinsey report, the cement industry is poised for significant growth, expected to reach 850 million tons per annum (t/a) by 2030 and 1350 million t/a by 2050. This expansion is supported by substantial progress in technological upgrades and the adoption of cutting-edge technologies, setting the stage for transformative shifts in manufacturing practices.

The cement industry is embracing the fourth industrial revolution—Cement 4.0—with significant strides in digitalization and automation to enhance efficiency, reduce costs, and improve sustainability. As manufacturers look to maximize their Return on Investment (ROI), the implementation of digital tools and processes becomes crucial. Here’s how advanced technologies are reshaping the cement industry:

Overcoming Operational Challenges with Digital Solutions

Condition-Based Monitoring (CBM) and Online Implement Monitoring: Traditionally, cement plants have relied on periodic manual checks to assess the condition of equipment. However, CBM allows for continuous monitoring of critical parameters like temperature and vibration, using sensors that provide real-time data. This shift not only enhances machine longevity but also optimizes maintenance schedules, reducing unexpected downtime and associated costs.

Predictive Maintenance for Bearings and Motors: Bearings are crucial components in cement plants, and predictive maintenance monitors bearing temperatures to warn of potential issues, allowing for timely replacement and avoiding costly breakdowns. Similarly, motors are the workhorses of cement plants, and keeping a close eye on motor conditions ensures they run optimally and alerts to potential failures in advance.

Manpower Optimization and Asset Feasibility

Leading cement manufacturers are keen on reducing manpower to streamline operations and focus human resources on more critical tasks. Automated systems in VRMs and cooling towers allow fewer personnel to manage operations, maintaining high efficiency and safety standards. Advanced systems in cranes and roller presses minimize human intervention, particularly in hazardous areas, thereby reducing risk and enhancing operational reliability.

Vibration Monitoring and Predictive Maintenance

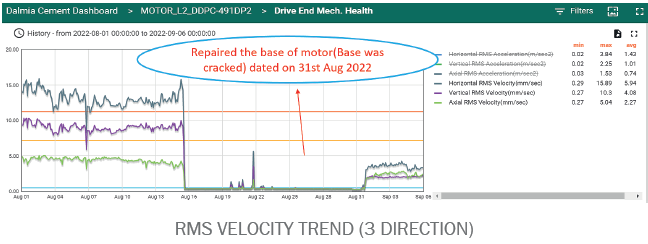

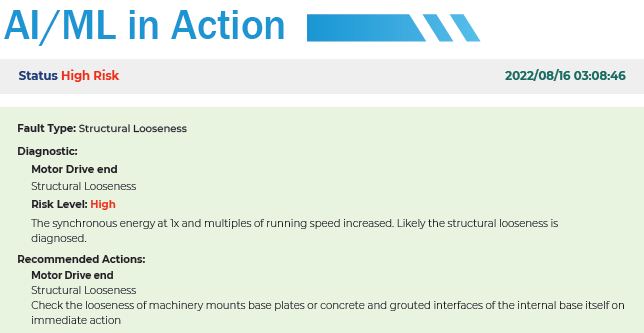

Vibration Monitoring: One of the standout features of digitalization in cement manufacturing is the ability to monitor equipment vibrations to predict failures before they occur. By setting threshold limits, the system can preemptively alert maintenance teams to potential issues, preventing costly unplanned shutdowns. This capability is essential for maintaining continuous production lines and avoiding significant financial losses due to equipment failure.

Lack of Tripping Protection: In some critical applications within the cement industry, there is a notable absence of tripping protection facilities. This deficiency means that immediate corrective actions cannot be taken in high-risk conditions, potentially leading to severe operational disruptions or safety hazards. Integrating advanced monitoring systems that can trigger automatic shutdowns or alerts can mitigate this risk significantly.

Predictive Maintenance in Clean Areas: Cement plants typically face challenges in maintaining equipment in ‘clean’ areas—zones that are critical for quality control but are sensitive to dust and other contaminants. Here, predictive maintenance can be particularly effective, utilizing data analytics to foresee and prevent failures without frequent physical inspections, which could compromise the cleanliness of these areas.

Predictive Maintenance in Gearboxes, Mills, and Kiln Installations: Gearboxes, mills, and kiln related installations are pivotal in cement plants, and predictive maintenance strategies here are critical for ensuring reliability and reducing unplanned downtime.

(Source by CIMCON Digital)

(Source by CIMCON Digital)

(Source by CIMCON Digital)

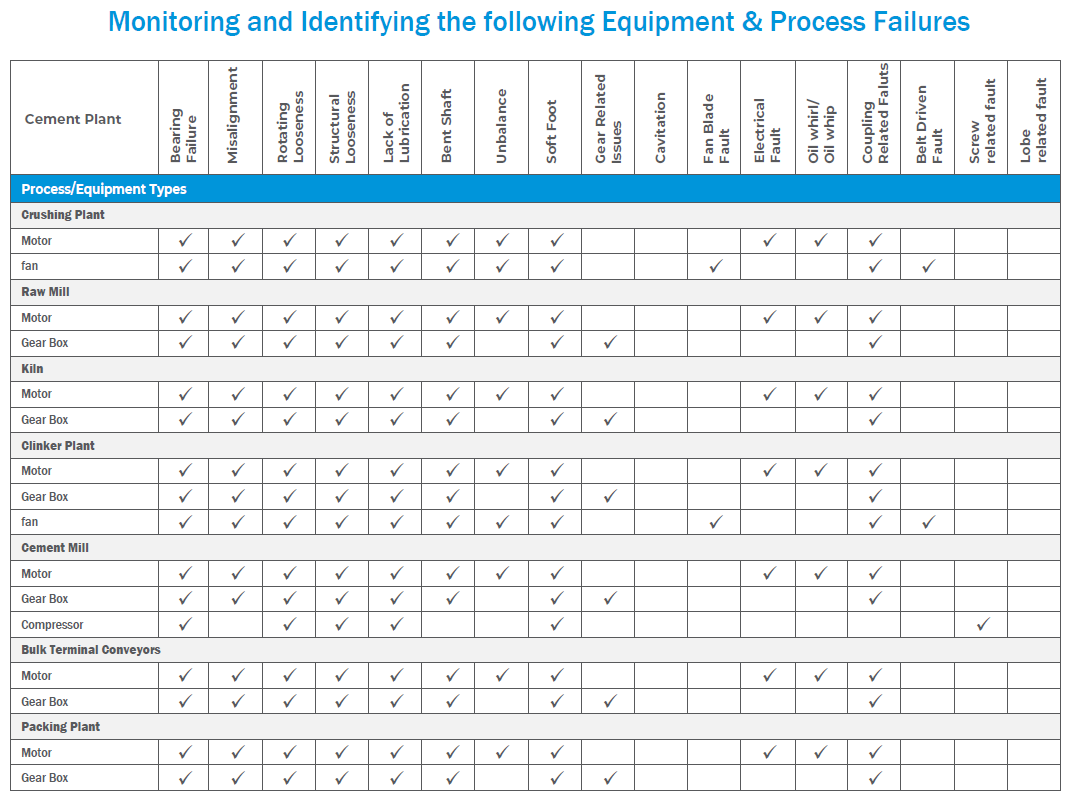

Below is a snapshot illustrating the faults that can be diagnosed by vibration monitoring system.

(Source by CIMCON Digital)

Digitalization and ROI: Calculating the Benefits

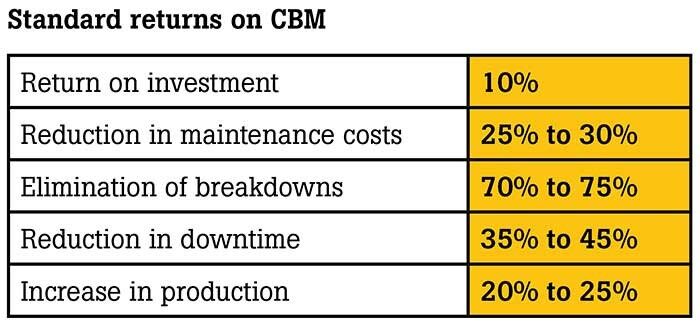

The shift to digital operations offers tangible benefits that directly impact the bottom line. By reducing manual interventions, optimizing maintenance, and enhancing equipment efficiency, plants can achieve a lower operational cost per ton of cement produced. For instance, implementing CBM and predictive maintenance strategies not only extends the life of the equipment but also significantly cuts down energy consumption—directly translating to cost savings and improved ROI.

Source: US DOE Operations & Maintenance Best Practices Guide

Deloitte Source (https://www2.deloitte.com/content/dam/Deloitte/de/Documents/deloitte-analytics/Deloitte_Predictive-Maintenance_PositionPaper.pdf)

Reducing CO2 Footprint through Digitalization

Energy consumption is a major contributor to the CO2 footprint of cement manufacturing. Digital tools that optimize energy use—such as smart thermostats in cooling towers and energy-efficient drives in cranes and VRMs—help reduce the overall energy demand of the plant. Furthermore, the use of alternative fuels and materials, monitored and optimized via digital solutions, contributes to a substantial decrease in CO2 emissions, aligning with global sustainability goals.

Conclusion: Integrating CIMCON Solutions

CIMCON Digital’s integration of its VIBIt solution and CIM IoT edge platform offers significant advantages for predictive maintenance in the cement industry. These technologies enable precise condition monitoring and real-time analytics, which are crucial for reducing downtime, minimizing maintenance costs, and enhancing productivity. For companies like Ultratech, JK Cement, Shree Cement, and Ambuja Cement, which are leading players in the cement industry, adopting these advanced solutions can lead to more sustainable and profitable operations.

By leveraging CIMCON’s solutions, these top cement manufacturers can benefit from enhanced operational efficiency and safety while also achieving significant environmental benefits. The transition towards digital technologies, often referred to as Cement 4.0, is essential for staying competitive in a rapidly evolving industry. It not only offers financial gains but also contributes to environmental sustainability by optimizing resource use and reducing emissions.

Incorporating technologies like CIMCON‘s enables these companies to maintain a competitive edge by ensuring their manufacturing processes are as efficient and environmentally friendly as possible. The journey towards a fully integrated digital cement plant involves complex technological upgrades but offers substantial rewards in terms of improved production capabilities and reduced ecological footprints.