VIBit - Battery Powered

Easy-to-Install, Battery Powered, Tri-axial Vibration and

Temperature Sensor for Anomaly Detection

Optimize Machine Uptime with VIBit – Battery Powered Intelligent Monitoring

for Enhanced Maintenance Efficiency.

What is VIBit-BP?

VIBit-BP is an intelligent, powerful, and compact battery-powered sensor that monitors the condition of machines or equipment to predict their failures in advance to avoid costly downtime, increase reliability, and reduce O&M costs. Designed to work in rugged industrial environment, VIBit-BP is a very compact and lightweight vibration sensor that can be easily installed on a range of equipment to detect abnormal vibrations and high temperatures without requiring any external power or connecting wires. This enables production and utility managers to know the real-time condition of their equipment.

What is the key role of VIBit-BP in industrial applications and

how does it achieve wireless data transmission?

VIBit-BP serves as a vital component in various industrial applications due to its unique capabilities as a self-contained, battery-powered sensor with no need for cumbersome wiring. It accomplishes wireless data transmission by harnessing the robust capabilities of BLE (Bluetooth Low Energy) connectivity. This wireless technology enables seamless and dependable transmission of both vibration and temperature data.

Why Choose VIBit-BP?

Choose VIBit-BP with confidence for your asset health and KPI monitoring needs. Here’s why:

Asset Health and KPI

Provides a holistic view of asset health and KPIs, enabling easy monitoring of crucial parameters

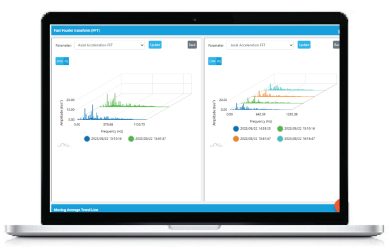

FFT Graphs

Offers FFT-based Frequency Domain Analysis for comprehensive vibration data frequency analysis, vital for machinery behavior and fault detection

AI/ML-Based Analytics

Offers advanced fault diagnostics by analyzing real-time and historical data to predict issues, thereby improving proactive maintenance through the use of AI and ML

Reporting

Offers robust reporting, delivering valuable equipment insights for informed decision-making and strategic planning

Easy Mounting

Designed for easy installation and can be conveniently mounted on equipment studs, simplifying deployment

User-Friendly Interface

Improves monitoring and offers advanced analytical tools and user-friendly interfaces for better machinery health insights

Reliable predictive maintenance with battery-powered sensors is transforming the way industries approach equipment monitoring and maintenance. These sensors provide cost-effective, real-time data that empowers maintenance teams to make informed decisions, reduce downtime, and ultimately enhance the efficiency and longevity of critical assets. As technology continues to advance, battery-powered sensors are expected to play an even more significant role in predictive maintenance strategies across various sectors.

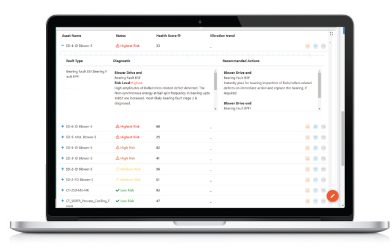

A dedicated page for customers to compare device health and performance. This platform grants access to site-level performance data and offers a Machine Efficiency Status feature for a quick overview of device health. It also includes an Overall Equipment Status feature for insights on equipment efficiency over time, aiding in informed equipment usage decisions.

The status of individual assets can be easily assessed through a color-coded system, and for added assurance, experts can delve deeper for verification. Additionally, real-time and historical waveform data is available to monitor and evaluate various parameters, providing a comprehensive view of asset health and performance.

Asset Name Customization enables user-friendly naming as per specific needs, enhancing asset management flexibility and clarity. User Friendly Widgets, with intuitive dashboards, simplify parameter monitoring and assessment, improving user experience and decision-making. Real-time waveforms provide dynamic data in waveform format for comprehensive process views, enabling quick responses and accurate analysis. These features empower efficient asset management and informed decision-making in a user-friendly, data-rich environment.

Benefits

Decrease Downtime

Help reduces unplanned downtime by predicting failures in advances

Eliminates Human Error

Analyzing large volumes of data manually is very difficult. VIBit keeps a close watch on all your assets and analyzes the data 24 X 7

Reduced Service Costs

Reduce service costs by planning well in advance and not needing to store multiple parts unnecessarily

Improved safety

Predict failures in advance helps the organizations to take action and make sure the machines are working in an optimal and efficient manner

Feel free to reach out to us today to discover how VIBit-BP can enhance your business and to initiate the setup of your vibration monitoring system.

VIBit-BP