Maintaining the health of assets is critical to the success of any business. Unforeseen asset breakdowns and downtimes hit businesses hard. Accordingly, preventative maintenance is of the utmost importance.

Good Machine health monitoring systems move businesses toward effective Predictive maintenance. Data is acquired from machines by installing various sensors on it. Then, this data is used to create visualizations which convey the health of the equipment. However, these systems cannot predict breakdowns or sense deteriorating asset conditions; they only alert the user when a problem has already occurred.

In order to use this data to prevent breakdowns, a skilled system operator would have to monitor the sensor data 24/7. This is a highly inefficient, costly use of business resources. Additionally, it is near to impossible for human to manually analyze thousands of data points each day.

Artificial Intelligence ( AI ) to the Rescue

The latest Artificial Intelligence (AI) technologies are coming to the rescue! AI is changing the world. Organizations around the globe are developing systems based on AI which increase business efficiency while reducing errors.

More than four decades ago, AI was used to create MYCIN, a system that diagnosed bacterial infections in humans and recommended antibiotics. Now, with advancement in this AI technology, machines can also be diagnosed. AI can derive machine health conditions and diagnostics.

AI provides insights into the state of a machine before it triggers the set alarm limits. AI models are trained on usual machine behaviors. Then, they can analyze the continuous flow of sensor data, searching for anomalies or patterns which warn of deteriorating machine conditions. The AI also indicates which factors are contributing to the impending asset failure; this gives the users actionable steps to prevent machine breakdown.

How it Works

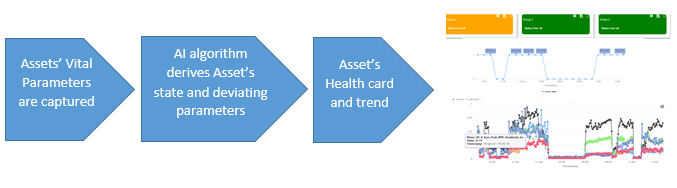

Sensors are installed to accurately capture vital parameters of the machine’s operation. The data generated by these sensors is sent to the Edge IoT Platform for storage and processing. Apart from showing trends of these parameters for real time monitoring, AI models deployed on the platform take use of trend data to derive the state of the machines. First, the data is fed into models to derive the typical behavior of the machines being monitored. The state of the asset as well as the parameters which affect its state are input. The AI analyzes the data feed, creating a statistical algorithm. This algorithm is then used to detect any unusual machine behavior going forward.

When it detects anomalous behavior, the AI model points to the contributing parameters and provides additional details about the degree of deviation from typical machine behavior as well as the rate of change of the machine’s behavior. Machine Health cards or health trends are used to visually give quick insight into asset health. A further drill down into the trend of the contributing parameter(s) helps detect the actual cause of deteriorating condition. This identifies what is failing and what needs maintenance.

Fig. 1: Machine Health Monitoring using KPI Cards and Drill Down

Benefits to Machine Operation & Maintenance Operator:

- Early warning provides ample time to operators to plan for repair and avoid higher repair costs.

- Helps avoid catastrophic asset breakdown

- Unlike humans, these algorithms can keep watch on data 24/7/365.

- There is no chance of errors due to a high data volume or operator fatigue.

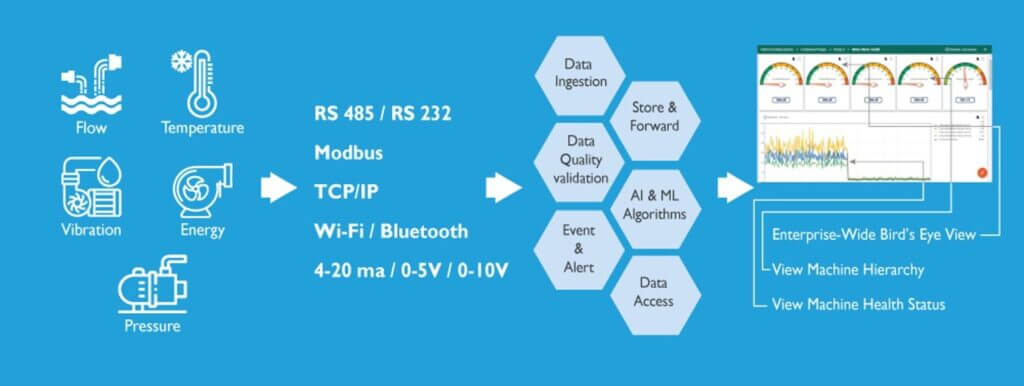

How the CIMCON Digital iEdge 360 Platform enables Machine Anomaly Detection and Predictive Maintenance Solutions for your Machines in the Plant or Utilities.

CIMCON Digital’s intelligent iEdge platform collects, integrates, and transforms machine health data using AI technology. Working with next-generation predictive maintenance solutions, CIMCON Digital provides actionable intelligence and early warning on machine health issues. This gives you the information you need to take corrective actions, preventing costly machine failures.

How it Works:

Our end-to-end solution provides plant operators with actionable insights into machine health and performance.

Fig –2 How Edge IoT Platform enables Machine Anomaly detection and diagnostics system.

Want to learn more? Watch our on-demand webinar and schedule an appointment with our Predictive maintenance expert.

Leave a Reply