Are you considering implementing an IIoT solution in your manufacturing environment? Are you unsure what type of IoT hardware you’ll need? It may appear simple to select hardware devices for process monitoring and control. However, there are some elements that should never be overlooked in a key manufacturing process. Hopefully, this blog will assist you in making an essential decision about which hardware device is ideal for you among the possibilities available in the market.

Why is it different from conventional industrial automation solutions?

The Industrial Internet of Things (IIoT) allows you to monitor and control equipment across large geographic areas or massive industrial locations. This is especially useful in difficult-to-reach, harsh, or isolated places where the operator/user does not have simple access for routine operations. With the deployment of numerous hardware devices in such a field setting, problems concerning remotely maintaining and upgrading all such equipment, as well as ensuring data availability and data security with continuous, dependable performance, arise. All of this should be kept in mind while picking IIoT hardware and an entire system.

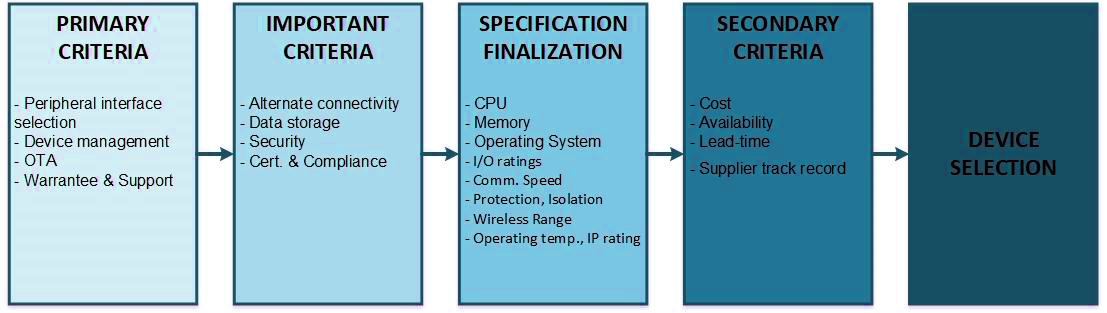

Primary criteria for

Peripheral Interface: A solution that allows you to work with existing solutions, such as old protocol interfaces. Many sectors may already have solutions in place. The demand is for a specific process or data that requires an improvement in IoT connectivity to improve manufacturing process efficiency. So, instead of replacing and re-installing new hardware, this is the best add-on / compact solution. For example, a single cellular modem with RS485 MODBUS interface and MQTT string conversion capabilities added to a cloud data centre may be capable of handling data from all floor equipment and serving the purpose.

A full-featured IoT Edge device solution is a better choice for some new/re-installation where target endpoints are more but in close proximity, as it can handle various process monitoring and control tasks with its multiple peripheral I/O and communication interface supports (like conventional PLC/RTUs), (ii) handles all network communication to the data centre (like IoT Gateway), and (iii) user interface support (like HMI/Mobile or web app), etc. A common integrated hardware solution may be more dependable and time-efficient than gathering and installing various device solutions in a panel, which increases the overall solution size and cost.

In some cases where potential future expansion is anticipated, the plant manager can count spares and buffer some I/O interfaces concurrently with an existing solution. Another alternative is to use a hardware device with modular flexibility to expand the number of I/O or communication interfaces in the future.

User Interface and Device Management: This is a fundamental differentiation between IoT device solutions and traditional industrial automation solutions. Because IoT solutions are designed to serve even little machinery or equipment, large volume, dispersed, and remote deployments necessitate quick and easy device installation, configuration, and management. Conventional keyboard / HMI / local PC based user interface alternatives are not ideal in this situation. Instead, for remote device administration, a simple mobile app that can connect devices through Bluetooth for local users or LAN, Cellular, Wi-Fi, and so on is more convenient.

Some high-end feature-rich device solutions may have a touch-based GUI display interface, which can be useful for installation or maintenance people because it eliminates the need for any external equipment or cabling.

OTA: Over the Air device upgrade should be regarded a standard feature in this case. With the variety of wired/wireless interfaces that IoT devices provide to connect multiple industrial assets, its data processing, logic algorithms, data analytics, any security lapse notice, and support for any future expansion plan, etc., upgrading device firmware or software run time may be required. Even automatic mass firmware and software updates become important for larger deployments.

Product Service and Support: While this is ideal for any industry/user, it is vital for the manufacturing industry. The cost of the hardware devices is typically a small percentage of the total project cost/budget, but it does not make them any less crucial. As a crucial selection factor, one must determine the manufacturer’s hardware device warranty and after-sales assistance for maintenance, etc. Any downtime in the industrial industry might result in a large loss.

Application-specific important criteria, can’t ignore

Alternate Connectivity: A device with a dependable network connection to the common data centre. This is not only for performance reasons, but also to have a redundant solution or to have the option of switching between many network connections. For example, if Wi-Fi access to the data centre is interrupted for some time, the device, if it has cellular connectivity, can auto-switch to cellular mode OR vice versa to guarantee that the data arrives on time.

Data Storage: In addition to dependable network connectivity, look for local device data storage features, memory capacity, and data retrieval mechanisms. Temporary loss of all included network connections may occur, for example, cellular signal strength is already low, SIM card is not active, and Wi-Fi router is turned off, in which case all data stored in field device’s local memory serves as a backup plan with the assistance of data retrieval mechanism. This is always vital for any manufacturing company to avoid losing production data, even if it is not real-time at the time.

Security: With everything connected to the network nowadays, even though the need for data security can be defined on an application basis, plant managers should define at least some minimal criteria. This is often used to reduce security risk in any manufacturing or process industry, whether for data availability, integrity, or even secrecy. For example, choosing a device that must support MQTTS over MQTT in order to establish an encrypted connection between broker and client.

Certification and compliance: Depending on the type of industry, product hardware (or total solution) compliance becomes a basic mandatory criterion for various manufacturing industries, such as medical equipment manufacturers, automotive industries, food industries, and so on. For others, it may simply be confidence in solution dependability. It is generally essential to choose a product that meets basic safety and EMI-EMC standards for the corresponding product category.

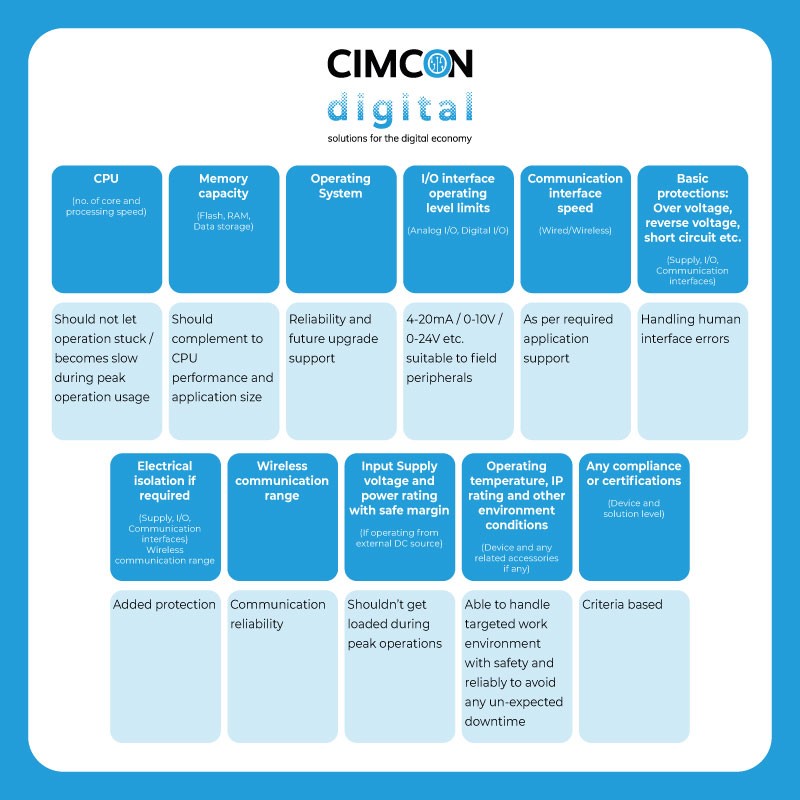

Hardware Specifications finalisation

Secondary selection criteria

With major criteria discussed there are few other aspects can take into account are cost, availability, lead-time, supplier track record-customer satisfaction survey etc. to be checked to avoid any uncertainty with decision you make.

Summary

And here is a summary chart for a quick reference to this blog discussion.