Cover Story

Ahmedabad and Boston, August 9th, 2023

Experienced business leaders play a crucial role in driving innovation and addressing the pressing needs of industries. They possess a unique vision, unwavering determination, and a deep understanding of the challenges and opportunities present in their respective fields. Among these remarkable individuals, Anil Agrawal stands out as one of the most successful business leaders, making significant strides in industrial transformation. As the CEO of CIMCON Digital, Agrawal has demonstrated exceptional leadership skills and propelled CIMCON Digital to the forefront of industrial transformation, cementing himself as a remarkable leader who continues to shape the industry’s future.9

Pioneering Industrial Transformation Agrawal embarked on a journey driven by his realization of energy consumption and inefficiencies within industries. Motivated by the potential of Industrial IoT (IIoT) technology to reduce energy consumption through enhanced machine efficiency, Agrawal founded CIMCON Digital to create a connected industrial world through digital transformation. With a dedicated team, CIMCON Digital translated customer challenges into scalable solutions, focusing on its Edge Platform products and services. The organization’s biggest challenge was overcoming the complex industrial landscape and educating firms about cutting-edge technology and the importance of adopting it to improve operations. It was vital to quantify the impact of IIoT and provide evidence of higher productivity and efficiency to accelerate adoption in the industry.

However, Agrawal’s leadership, customer-centric approach, and strategic partnerships propelled CIMCON Digital to emerge as a leader in industrial transformation. Agrawal was successful in reducing energy consumption by a staggering 17%, addressing the pressing needs of the industry with resilient digital solutions and overcoming the industry

players’ resistance to change.

CIMCON Digital: Empowering Digital Transformation

CIMCON Digital is a leading Edge IoT Platform and solution provider specializing in driving digital transformation in the Manufacturing, Water, and Infrastructure sectors. With a comprehensive platform and solutions, CIMCON Digital addresses critical use cases such as condition monitoring, predictive maintenance, energy analytics, and process optimization. The organization’s technology solutions have empowered Fortune 500 companies across various industries, including Pharma, Cement, Automotive, FMCG, and Steel.

Established initially as a division of CIMCON Software (I) Pvt. Ltd., CIMCON Digital is driven by a relentless focus on facilitating a digital world through innovative products and solutions. With over 35 years of experience, CIMCON Digital has worked diligently to seamlessly integrate technology into the background, allowing users to witness the outcomes delivered without being burdened by the underlying technology. The organization aims to provide tangible results, such as improved customer satisfaction, enhanced margins, and the ability to accomplish more with less through the digitalization of certain tasks.

By leveraging CIMCON Digital’s offerings, organizations can maximize efficiency, reliability, and operational excellence. The company’s iEdge 360 IoT Platform empowers companies to unlock the power of Industry 4.0 and embark on a digital transformation journey, all while promoting sustainability and net-zero initiatives. With CIMCON Digital, companies can harness the potential of technology to transform their operations, optimize asset performance, and drive toward a connected and efficient future.

Disrupting Traditional Approaches

CIMCON Digital’s platform has successfully disrupted the traditional way of working by revolutionizing asset maintenance practices. Traditionally, maintenance relied on time-based inspections and preventive measures tied to run hours, leading to unplanned breakdowns, increased spare costs, and reduced machine efficiency. However, CIMCON Digital’s solution introduces a technological shift in asset monitoring. By swiftly installing real-time sensors and connecting them to the plant Wi-Fi network, customers can receive machine health alerts within hours. This enables them to prioritize their limited resources and deploy

them where they are most needed, improving machine reliability and efficiency. With the AI/ML-based software embedded in the platform, continuous monitoring is provided 24/7, 365 days a year. This means that thousands of equipment assets can be monitored simultaneously, empowering customers with proactive maintenance actions and peace of mind. By disrupting the traditional approach to asset maintenance, CIMCON Digital’s platform empowers organizations to optimize their operations, reduce downtime, and maximize machine performance through real-time insights and predictive capabilities.

Introducing VIBit: A Game-Changing Solution

The growth of CIMCON Digital was catalyzed by the introduction of its VIBit solution in October 2021. This groundbreaking solution provided valuable insights into machine operations, offering early warning indicators for machine health anomalies, fault diagnostics, and repair recommendations. Positive word-of-mouth spread throughout the industry as customers began reaping the benefits, such as reduced machine downtime and improved energy efficiency.

The adoption of CIMCON Digital’s solutions by these satisfied customers led to a ripple effect, as other companies and peers took notice and started embracing the organization’s offerings. This widespread adoption and scale marked a pivotal turning

point, triggering significant growth for the organization.

Cutting-Edge IoT Solutions

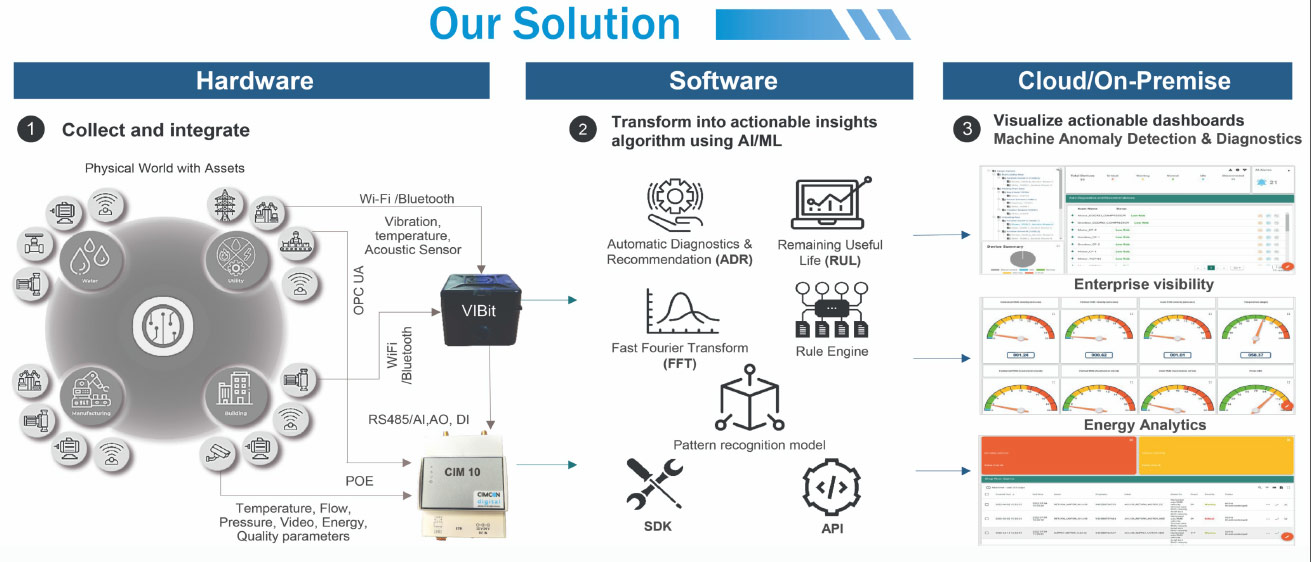

CIMCON Digital specializes in providing cutting-edge IoT solutions and services. With a comprehensive platform, the organization offers a range of capabilities to optimize operations and drive business growth for its clients.

IoT Hardware

CIMCON Digital offers a diverse range of edge sensors to monitor various parameters such as vibration, noise, and temperature. These sensors are instrumental in collecting crucial machine data for analysis. In addition, its edge gateway facilitates seamless connectivity with machines utilizing different industrial protocols.

Advanced Analytics Software

Leveraging advanced analytics and AI/ML capabilities, CIMCON Digital’s software transforms raw machine data into actionable intelligence. This powerful software enables early warnings for machine anomalies, facilitates fault diagnostics, and recommends appropriate actions. Clients can make informed decisions through analytics software to enhance efficiency and optimize their operations.

Visualization Layer

CIMCON Digital’s platform includes a visualization layer that empowers stakeholders, ranging from C-suite executives to operations and maintenance team members. This layer presents valuable insights and foresight derived from the collected data. CIMCON Digital enables stakeholders to take timely and informed actions based on the presented data by providing intuitive visualizations.

Smart Solutions

CIMCON Digital is revolutionizing the manufacturing industry with its innovative solutions.

Smart Manufacturing

CIMCON Digital’s iEdge 360 IoT Platform seamlessly integrates with production line machines, harnessing data to enhance yield, efficiency, capacity utilization, and asset availability. By leveraging this platform, manufacturers can respond swiftly to changing demands, ensuring optimal performance and productivity.

Smart Water

Water and wastewater management becomes highly efficient with the CIMCON iEdge 360 IoT platform. By leveraging IoT technology and real-time data collection through sensors, potential water system failures can be detected, reducing the need for manual inspections. Water utilities can harness the power of data and analytics to monitor water quality parameters, automate irrigation and sewage management, and avoid wastage of water and time, ultimately ensuring reliable water management.

Smart Infrastructure

CIMCON Digital’s iEdge 360 IoT platform empowers facility managers to transform their buildings into smart structures. By deploying a range of sensors and actuators, valuable building data is collected and analyzed, leading to optimized operations and the ability to predict equipment failures before they occur. This technology enhances safety, security, comfort, and overall infrastructure performance.

Smart Everything

CIMCON Digital is at the forefront of smart technology, enabling connectivity and intelligence in everyday devices. From refrigerators to locks to shoes, the iEdge 360 IoT platform facilitates the integration of smart technology into various aspects of our lives. CIMCON Digital drives innovation and sets the stage for a fully connected and intelligent world.

How CIMCON Does It?

iEdge 360, Intelligence at the Edge: CIMCON Digital’s iEdge 360 platform is a central hub for collecting and integrating sensor data. By transforming this data, it becomes readily available for real-time analysis by digital machine experts, providing accurate and actionable insights. This comprehensive platform offers interfaces, protocols, networking capabilities, and computing power, enabling seamless implementation of smart solutions.

CIMcloud, Scaling Digital Transformation: To facilitate large-scale digital transformation, CIMCON Digital offers its own CIMcloud application. This powerful tool allows for the provisioning, authentication, authorization, and management of hundreds of thousands of devices. With a user-friendly web-based management application, CIMcloud provides visualization and analytics, allowing plant operations to be monitored through key performance indicators (KPIs).

CIMdata, Unleashing the Power of Data: At the core of digital transformation lies the power of data, and CIMCON Digital’s CIMdata solution extracts invaluable insights from this wealth of information. Leveraging advanced Machine Learning algorithms, CIMdata listens to the data, offering plant operators actionable advice to prevent costly machine failures and improve the bottom line.

Advancing Products and Services Through Artificial Intelligence

CIMCON Digital furthers its products and services by embracing a data-driven approach to innovation. Agrawal believes in leveraging machine learning and generative AI technologies to continuously improve its offerings in two ways, one for customers and one for the business. The company is committed to creating ChatGPT-powered insights by training the model with its custom data to create its chatbot, Muni. Through Muni, CIMCON can relay vital asset updates to clients in a straightforward and interactive manner. For example, clients can ask questions like, “How is my plant doing today?” or “Which machines should I inspect today?” to better understand their plant health. In addition to the chatbot, the company will use this revolutionary new

natural language processing technology to create not only text-based information but also graphical representations of

essential data for clients to gain a visual understanding of their current situation.

The company is also leveraging generative AI for creating more efficient internal processes. Agrawal mentions, “The idea is to drive productivity within the firm through generative AI to meet the demand for the product.” He aims to use this technology to provide more content for customers through its robust content generation capabilities combined with the team’s expertise. It will also be a great help to the customer success team, providing an interactive FAQ chatbot to address any client concerns. By harnessing the power of these cutting-edge technologies, CIMCON Digital helps customers identify opportunities for energy optimization and sustainable operations in a simple and efficient manner.

Seamless Technology Solutions

CIMCON Digital’s technology has proven instrumental in providing customers with a seamless experience, delivering significant benefits across multiple aspects. Firstly, the technology has enabled customers to reduce downtime, a critical concern in manufacturing industries. By leveraging the edge platform, customers can proactively monitor machine conditions, detect potential issues early on, and implement preventive measures to avoid unplanned downtime.

Secondly, the technology has enhanced operational efficiency for customers. Through advanced analytics and AI/ML capabilities, the platform transforms raw machine data into actionable insights. This empowers customers to optimize processes, identify bottlenecks, and make data-driven decisions that drive efficiency and productivity.

Moreover, CIMCON Digital’s edge platform supports customers in accelerating their digital journey. The platform offers scalability and flexibility and caters to various use cases such as condition monitoring, predictive maintenance, energy analytics, and process optimization. This versatility allows customers to seamlessly integrate the solution into their existing technology landscape, maximizing their investments and enabling a smooth transition to enhanced operational capabilities.

Overall, CIMCON Digital’s technology solutions empower customers to elevate their operations, minimize downtime, and achieve higher levels of efficiency. By delivering a seamless experience, the technology enhances customer productivity and profitability across industries.

Leadership Philosophy

Anil Agrawal’s customer-first leadership philosophy permeates every aspect of CIMCON Digital. Under his guidance, the organization thrives on collaboration, effective communication, and mutual respect, enabling teams to deliver innovative solutions that exceed customer expectations.

Encouraging a growth mindset, Agrawal fosters continuous improvement and adaptation to evolving customer needs. Emphasizing ownership, he instills a sense of accountability and commitment to delivering exceptional results. Moreover, a sense of urgency drives CIMCON Digital’s proactive approach, ensuring timely and effective solutions to address customer problems.

This customer-centric leadership approach has fostered a thriving and innovative organization. CIMCON Digital’s commitment to innovation and customer-centricity ensures it remains at the forefront of the digital transformation landscape. Empowering industries for a connected and efficient future, the company continues to pave the way for transformative advancements.

CIMCON Digital is a pioneering Edge IoT Platform and solution provider, specializing in driving digital transformation through the utilization of Generative AI and machine learning in the Smart Manufacturing, Water, and Infrastructure sectors.