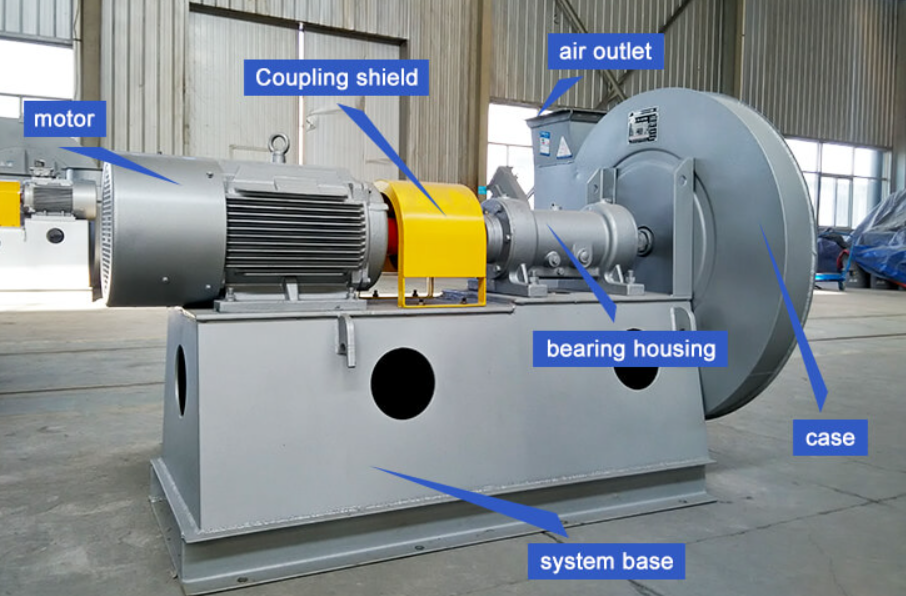

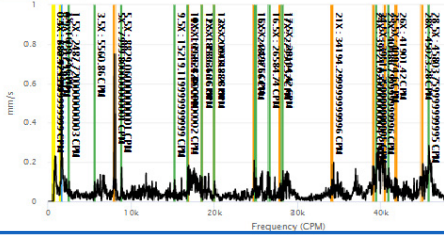

The VIBit is CIMCON Digital’s tri-axial vibration, temperature, and acoustic sensor for machine anomaly detection. It is simple to install on a variety of machinery, using Bluetooth to connect to your smartphone in addition to compatibility with the Modbus protocol CIMCON iEdge 360 gateway. It automatically will alert you via e-mail and SMS to machine faults such as rotor imbalance, lubrication issues, centrifugal pump abnormalities, gear drive abnormalities, and much more. The device works wonderfully in many industries, including the textile, pharmaceutical, hospitality, mining, and health industries, this article presents just a few of its uses in the cement industry.

VIBit is an intelligent, powerful, and compact sensor that can be used to monitor the condition of critical equipment in the cement industry such as the kiln fan. Through its monitoring capabilities, this sensor helps cement companies prevent unplanned downtime